$50 3D-printed part replaces $42,000 medical prosthetic hand

Tuesday, January 27, 2015 by: Ethan A. Huff, staff writer

Tags: 3D printing, prosthetic hand, medical device

- Drug company CEOs targeted in government crackdown of illegal marketing

- Cultivate vibrant health and a clear mind with the wisdom of Ayurveda

- Family sues pharmaceutical company over child brain damaged by flu vaccine

- The aloe vera miracle: A natural medicine for cancer, cholesterol, diabetes, inflammation, IBS, and other health conditions

- Oxygenate your body - How to restore oxygen balance and help prevent disease

- NSA has infected computer hardware with spyware at the firmware level: even NEW computers are infected from day one

- Over 30,000 scientists say 'Catastrophic Man-Made Global Warming' is a complete hoax and science lie

- Water purification breakthrough revealed: AquaTru countertop water purifier removes 128 toxic chemicals, fluoride, heavy metals and more

- GMOs Alter the Genetic Make Up of Our Healthy Bacteria

- 'Miracle grass' encourages longevity while dispelling disease

- How to heal cavities naturally

- Four supplements that will benefit almost everyone

- Whole Body Detox (Part 1): Lymphatic Cleansing With Rebound Exercise

- Nature's most powerful antibiotics in one bottle

- Sherri Tenpenny warns parents about safety of vaccines in NaturalNews interview

- Horsetail and oat straw are two powerhouse herbs for calcium

- AP investigation: US hospitals nowhere near ready for Ebola

- Blood test identifies changes in gene which are linked to suicidal thoughts and behaviors

- Curcumin slays cancer cells in their tracks

- The REAL FAKE NEWS exposed: '97% of scientists agree on climate change' is an engineered hoax... here's what the media never told you

- Foods, herbs, and supplements that kill cancer - safer and more effective than drugs

- The aloe vera miracle: A natural medicine for cancer, cholesterol, diabetes, inflammation, IBS, and other health conditions

- Water purification breakthrough revealed: AquaTru countertop water purifier removes 128 toxic chemicals, fluoride, heavy metals and more

- Boost Low White Blood Cell Count and Immune Function Naturally

- Dr. Blanche Grube explains when it is wise to keep your wisdom teeth at the Holistic Oral Health Summit

- What Your Doctor did Not Tell You about Food Intolerances

- Magnesium and your health

- Study Finds Chinese Red Yeast Rice Good for Your Heart

- Health secrets revealed on the next NaturalNews Talk Hour

- Health benefits of Bromelain: An anti-inflammatory enzyme

- Avoid vaccines and use these top four natural remedies for flu prevention instead

- If given a fair choice, most consumers would choose alternative medicine over conventional health care

- Bill Gates GMO Zombie Eggs

- The best, and worst, laundry detergents with 1,4-dioxane contamination

- Zeolite detox myths busted: In lab tests, zeolites do NOT bind with aluminum, lead, uranium, mercury or cadmium... only CESIUM

- Food addiction more than willpower, a serious disease suffered by many

- The REAL FAKE NEWS exposed: '97% of scientists agree on climate change' is an engineered hoax... here's what the media never told you

- Red Cabbage Found to Contain 36 Anti-Cancer Anthocyanins

- Beat cancer with 35% hydrogen peroxide

- The 10 worst toxins hidden in vitamins, supplements and health foods

- Four supplements that will benefit almost everyone

- Untested vaccines causing new wave of polio-like paralysis across India

- Canadian agency attacks Jenny McCarthy for demanding mercury-free vaccines

- Curcumin slays cancer cells in their tracks

- Bill Gates says vaccines can help reduce world population

- Top foods, herbs and supplements to keep on hand in the event of a nuclear crisis

- The United Nations 2030 Agenda decoded: It's a blueprint for the global enslavement of humanity under the boot of corporate masters

- Before his death, father of ADHD admitted it was a fictitious disease

- Flu vaccines causing massive spike in deaths of elderly across the UK, warn health officials

- Vitamin E kills off cancer cells and prevents their reproduction, study finds

- Vaccines lower immunity

- Boost Low White Blood Cell Count and Immune Function Naturally

- Vitamin B-12 warning: Avoid cyanocobalamin, take only methylcobalamin

- Apricot Seeds Kill Cancer Cells without Side Effects

- EPA advisor admits the agency is funneling billions to climate groups ahead of Trump’s return to White House

- Newly released JFK files reveal Pentagon's role in creating Lyme disease and covid in the same lab

- Eleven days before Iran bombed Tel Aviv, my microscope revealed haunting images of EXACTLY what would happen

- Morphic resonance “remote viewing” reveals iconic Middle East images of stealth bombers, a falcon and a one-horned ram

- Mike Adams releases country western hit single: Goin’ Back in Time is Comin’ Home

- DECENTRALIZED SPIRITUALITY and the true teachings of Christ: Overcoming the censorship, threats and lies of organized religion to truly know God and the Universal Christ

- Global leaders unite to clamp down on “misinformation” with UN-backed Cascais Declaration

- BOMBSHELL: Covid-19 mRNA nanoparticles EMIT LIGHT SIGNALS that communicate MAC addresses used for self-assembly inside the blood vessels

- I Want My Bailout Money – new song released by Mike Adams

- HEALTH SECRETS: How to Instantly Block MSG Toxicity Using Natural Substances (and the secret of Methylene Blue)

- The Health Ranger releases “Vaccine Zombie” song and music video, using AI-animated zombies for the music video

- BOMBSHELL: Internal Pfizer documents exposed and reveal at least 16 PERCENT of their mRNA vaccine "adverse events" are REPRODUCTIVE DISORDERS

- Two containers with completed ballots fall out of truck in Florida

- BOMBSHELL: DNA testing kits are a SCAM to develop ethnic-specific bioweapons

- Amazing microscopy photos reveal how freezing crystals attempt to mimic electronic structures they are touching

- RFK Jr. clears key hurdle: Sen. Susan Collins backs controversial HHS nominee, signaling a new era for health policy

- HYSSOP: What research reveals about the health benefits of this ancient holy herb

- The Coming Gold Revaluation: Strategic Financial Realignment in an Era of Dollar Collapse

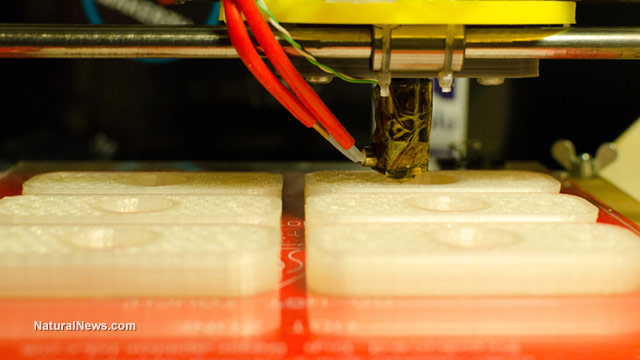

After spending about $42,000 on a conventional prosthetic hand, 53-year-old Jose Delgado, Jr., who was born without most of his left hand, was left wanting. The seemingly lifelike hand doesn't grip as well as he would like, and the ring and pinky fingers don't work at all, and are there primarily for aesthetic purposes.

It was really his only option until 3D printing came along, offering regular people the opportunity to design their own tools, parts and, in this case, synthetic limbs, for a fraction of the price of their conventional counterparts. Interestingly enough, it really wasn't that hard for Simon, a 3D-printing expert, to design a better prosthetic hand for Delgado, and for a fraction of the price.

Simon calls it the e-NABLE Hand, and it only cost him about $50 to make, or about one-tenth of 1 percent of what Delgado paid for his original prosthetic hand from conventional medicine. And the best part about e-NABLE is that it is more functional, grips better and is incredibly durable, something that Delgado isn't able to say about his other hand.

"It's useful for carrying boxes," stated Delgado about the functionality of the "Cyborg Beast," the colloquial name for the 3D-printed hand. "This one [the $42,000 hand], if I grab something, it'll just fall out. These have more grip," he added, pulling on the slick, black appendages attached to the Cyborg Beast.

$50 3D-printed hand has full movement while $42,000 one is severely limited

The way it works is a series of non-flexible cords on the underside of each finger is attached to a tensioning block on the top rear of the device -- Simon refers to this block as "the gauntlet." As Delgado bends his wrist downward, tension is created and the Cyborg Beast closes its fingers, allowing him to pull or lift objects weighing up to about 20 pounds.When the wrist is returned to a normal resting position, a series of non-flexible cords on the top part of the device is pulled, opening up the hand in the same way as a real hand would remain open, with the fingers slightly curved inwards. These corresponding movements allow Delgado to close his hand naturally by simply bending his wrist about 20-30 degrees downward, and opening it back up by returning to the natural position.

You can see the "Cyborg Beast" in action here:

YouTube.com.

"The 3D one has all the function of the fingers, so I like that better," expounds Delgado with a smile, recognizing the beauty and simplicity of the $50 work of art.

This is the future of open-source medicine, folks -- the freedom of everyday folks to create what they need from their own 3D printers for a mere fraction of the price of what the corporate system charges. According to 3D Universe, the machine used to print the Cyborg Beast costs between $1,000 and $2,000 depending on the setup, and such machines are only becoming cheaper over time.

"When you combine that kind of technology with the collaborative power of the Internet, the inherent generosity of human beings, and a global open source community, truly remarkable things start to unfold," explained Simon.

"Less than a year after being formed [the e-NABLE volunteer community], more than 650 volunteers have joined in to help provide inexpensive assistive technologies (such as 3D printed prosthetic hands) for underserved communities everywhere."

You can learn more by visiting eNABLingTheFuture.org.

Sources:

http://www.3duniverse.org

http://youtube.com

http://www.naturalnews.com

http://enablingthefuture.org

3D printing at FETCH.news

Get independent news alerts on natural cures, food lab tests, cannabis medicine, science, robotics, drones, privacy and more.

Take Action: Support Natural News by linking to this article from your website

Permalink to this article:

Embed article link: (copy HTML code below):

Reprinting this article:

Non-commercial use OK, cite NaturalNews.com with clickable link.

Follow Natural News on Facebook, Twitter, Google Plus, and Pinterest

Science News & Studies

Medicine News and Information

Food News & Studies

Health News & Studies

Herbs News & Information

Pollution News & Studies

Cancer News & Studies

Climate News & Studies

Survival News & Information

Gear News & Information

News covering technology, stocks, hackers, and more

"Big Tech and mainstream media are constantly trying to silence the independent voices that dare to bring you the truth about toxic food ingredients, dangerous medications and the failed, fraudulent science of the profit-driven medical establishment.

Email is one of the best ways to make sure you stay informed, without the censorship of the tech giants (Google, Apple, Facebook, Twitter, YouTube, etc.). Stay informed and you'll even likely learn information that may help save your own life."

–The Health Ranger, Mike Adams